Piling Methods

There are a number of different ways in which piles can be installed.

The most suited to your project will likely be decided by the Main Contractor, Piling Subcontractor and Structural Engineer.

This will be based on a number of different factors, including:

- Site ground conditions – is the ground good for piling? Are there services under the ground?

- Size of piles – if they are much smaller or bigger than average choice of method use may be restricted

- Site access – can the equipment required get to pile locations? Smaller rig options may be an option

- Commercial – which method is most cost effective for your particular job?

- Local authority – what restrictions are there on noise and vibration? How close are piles to neighbouring buildings?

The main options are:

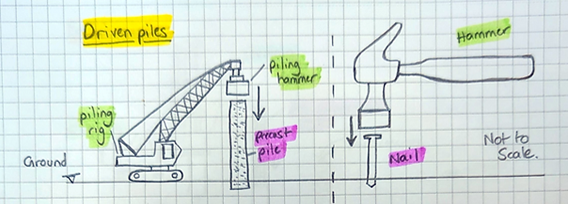

1. Driven Piles: Driven piles are forcefully hammered, driven, or pressed into the ground using a pile driver or piling hammer.

This method is used for precast concrete piles, steel piles, or timber piles.

To help visualise – the piling rig acts like a giant hammer

Driven Piles are usually better commercially but usually have very high noise and vibration implications.

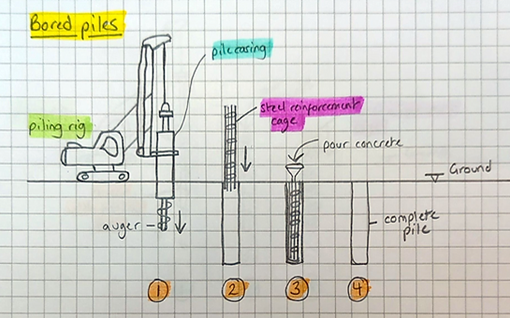

2. Bored Piles: Bored piles are created by drilling a hole into the ground using an auger.

After the hole is formed, it is filled with concrete and reinforcement is added.

The majority of ground would collapse in on itself if the hole formed by the auger was left open so a pile casing may be used to support the ground.

Bored piles are commonly used for deep foundations in areas with difficult ground conditions.

1: Drill down and install casing, 2: Insert steel reinforcement cage, 3: Pour concrete, 4: Remove pile casing (sometimes casing is left in the ground permanently)

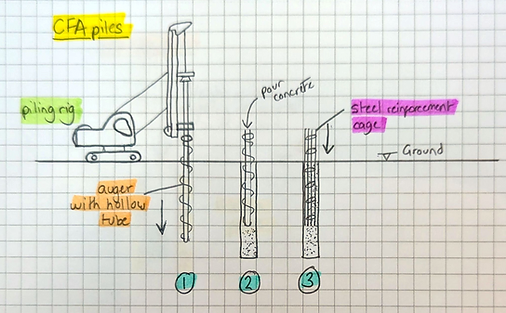

3. Continuous Flight Auger (CFA) Piles: CFA Piles are formed by drilling into the ground with a continuous auger.

As the auger is withdrawn, concrete is pumped through a hollow tube in the auger, displacing the soil and forming the pile.

CFA piles don’t require casing in most cases, but sometimes casings are used anyway as they help improve vertical tolerance.

Pile casings have the potential to reduce the amount of concrete required – less or no concrete should seep through to the ground.

1: Drill down, 2: As auger is rotating and being removed, the displaced ground is being bought up with it whilst concrete is being poured through the hollow tube in the auger, 3: Install reinforcement cage

CFA Piles are not suitable for sites where there are loads of underground services.

Compared to other methods, it is harder to keep site clean during works.

4. Micropiles (Mini Piles): Small-diameter piles, typically less than 300mm, that are drilled into the ground using specialised equipment. They are commonly used in areas with limited access or restricted working space.

Same install method as bored piles but smaller in size.

5. Helical Piles (Screw Piles): are “screwed” into the ground using hydraulic motors or torque machines. They are typically manufactured with high grade steel.

Think of these as installing very large screws into the ground. Same install method as driven piles but visualise a screw instead of a nail.

Other considerations

It’s worth finding out which method will be used on your project to help understand what space will be required and any associated health and safety aspects.

I recommend watching the install on site for the first couple of piles in full and making a mental note of each of the stages.

Hit: to help understand how angering works, visualise a cork screw going into the ground and bringing up spoil.

Definitions

Piling hammer – uses hydraulics, diesel, vibrations or a large weight to force piles into the ground

Precast – manufactured in a controlled environment away from the construction site

Auger – a very large drill bit, an attachment to a piling rig

Pile casing – also known as a pile liner or pile sleeve, is a hollow tube which is installed during the piling process to prevent collapse of the surrounding ground. Can be made of steel or concrete and is sometimes left in permanently

Tolerance – acceptable differences from the planned measurements. An example of this is according to British Standards tolerance for piles vertically at any level is 1 in 100

Spoil – waste material brought up during any digging works.

Posts to Follow

We plan to go into more details about piling and add sections on:

- Logistics

- Temporary Works

- Build Sequence

- Health, Safety & Environment

- Quality

- Programme

- Commercial

Please let us know if you found this post useful using the chat function. We’d love to hear from you – is there anything in particular you’d like for us to focus on next?