Piling Quality

Quality refers to the standard of workmanship, materials and processes used during construction.

It involves adhering to design specifications, industry standards and best practises to ensure the end product achieves the intended performance and longevity.

Where Quality is managed well it can improve durability, functionality and aesthetics of the finished product. For piling, quality of aesthetics is not important as they are mostly under ground and not visible.

There are two quality processes in construction: Quality Assurance and Quality Control. The diagram below illustrates their relationship.

Quality Assurance (QA) is understanding what is required to achieve the desired quality. It includes how it will be managed and any systems that will be used.

Quality Control (QC) – the act of monitoring the works taking place.

Piling Quality Assurance

The plan for how Quality Assurance will be managed will be documented and should be submitted for review by the Piling Subcontractor.

This will be in the form of a Trade Quality Plan (TQP) or similar. It’s worth reading this document as a starting point. Some considerations which should be mentioned:

Piling Design and Planning: plan detailing how works will be designed and undertaken to comply with industry standards, design specifications and best practices.

Quality Policy and Guidelines: Outlines the organisation’s commitment to quality and sets the expectations for quality standards.

Training and Competency: Ensure that all personnel involved in piling activities are adequately trained, qualified, and competent to perform their respective tasks.

Material Procurement and Testing: procedures for sourcing, inspecting, and testing piling materials (steel, concrete etc.) to ensure they meet required specifications and standards.

Equipment Calibration and Maintenance: calibration and maintenance of piling equipment is essential for accurate performance. Establish procedures for equipment inspection, maintenance, and documentation.

Piling Quality Control

The plan for how Quality Control will be managed will also be documented. This will be in the form of an ITP (Inspection Test Plan) or similar. Sometimes an ITP will be included as an attachment to the TQP. It should include:

Reference Drawings and Specifications: list of latest revision drawings and specifications the piling works are being done to

For each point below, When, by Who and How itwill be recorded:

- Calibration of surveying and piling equiptment

- Checking setting out of piles

- Compliance of any materials used – concrete and steel

- Real-time monitoring and data collection during pile installation

- Pile testing methods

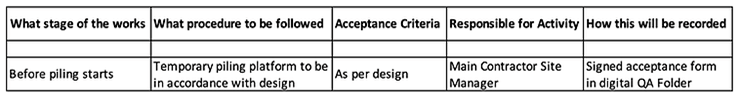

Example of a row in an ITP

Tips

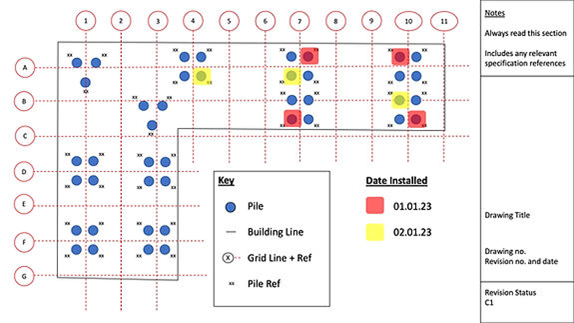

It is worthwhile marking up the piling general arrangement drawings either physically or digitally so there is a record of when each pile was installed.

This will make it easier to track concrete curing and testing records as it will become the main referencing document.

Example Piling Progress Drawing

Definitions

Trade Quality Plan (TQP) – document outlining the quality system to be used for the works. Including what standards are to be compiled with, the scope of works and roles and responsibilities.

Inspection Test Plan (ITP) – could be included in the TQP. Document highlighting when, how and who’s responsible for each inspection, test or survey required.

Posts to Follow

We plan to go into more details about piling and add sections on:

- Programme

- Commercial

Please let us know if you found this post useful using the chat function. We’d love to hear from you – is there anything in particular you’d like for us to focus on next?