Substructure Design

Design consultants assess the ground conditions, use of the proposed building and plan what Substructure elements would be best suited

There are many different types of substructure systems the structural engineer can choose from. These options will be explored in our next post – Types of Substructure.

We will be exploring pile caps for the remainder of this post but the design principles can be applied to the other types.

As with all elements of work, my recommendation would be to start by finding the relevant drawings.

In the case of Substructure, these will be under the Structural Engineer section and likely labelled ‘Ground Floor General Arrangement Plans’ and ‘Foundation General Arrangement Plans’.

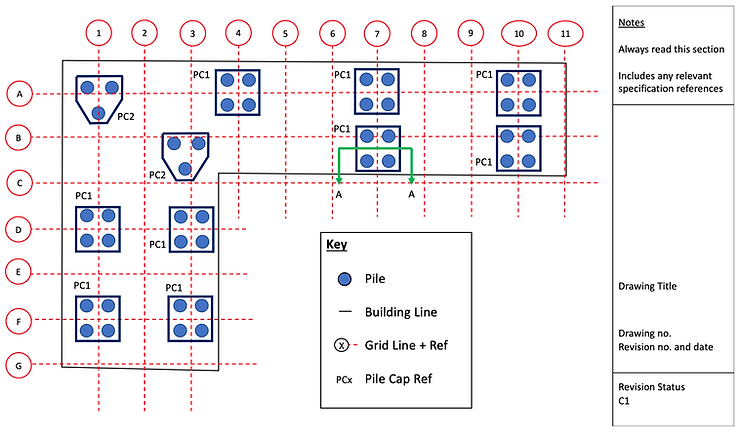

Example Foundation GA Drawing

In the example above, there are two difference types of pile caps labelled PC1 and PC2.

Note: the green arrows on the drawing with reference A-A refer to a section drawing.

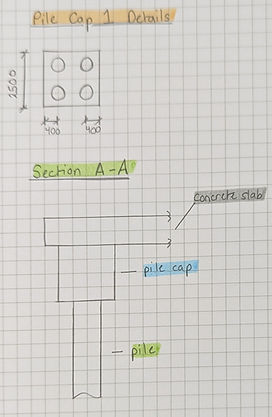

You would expect a number of section and detail drawings accompanying the plan drawings if they are not included as extracts on the main GA. This may look like the example below for pile cap 1:

This shows you dimensions for the Pile Cap and how it sit’s in relation with the rest of the structure. Think of a section showing you a slice through the building.

Structural Engineers considerations when designing Substructure

1. Soil Investigation: Understand what ground the substructure will be in. Some soils are better at supporting structures than others. This information can be found in a Site Investigation Report which should be available on your project.

What is the bearing capacity of the ground?

What is the potential for settlement?

2. Water Table: Account for groundwater levels and potential water-related issues that might affect the substructure’s stability. If the water level in the ground is high this could cause damage to foundations.

How high in the ground is the water table?

Will this be an issue for our designed substructure?

3. Load Analysis: Determine the loads the substructure must support. This includes dead loads (permanent), live loads (temporary), wind loads, if there’s any seismic loads, etc.

What is the weight of the structure?

What will be in the building? How much loading will it impose?

What are the average wind levels in the area? Is there a lot of snow that could load the roofs?

Sometimes the load during the construction phase is higher than what the building has been designed to take in the permanent state. For example, the structural engineer would need to run a calculation to check if the structural slab can take the weight of the access equipment planned to be used on the slab.

Scissor lift – a type of access equipment which may be required on structural slabs

4. Foundation Type: Select appropriate foundation types such as strip footings, isolated footings, raft slabs, piles, etc., based on soil conditions and loads.

5. Structural Materials: Choose the right materials, such as concrete, steel, or composite materials, considering strength, durability, and compatibility.

6. Structural System: Integrate the substructure design with the overall structural system of the building, ensuring a seamless load transfer.

How many columns are required in the building?

7. Buildability: Design elements that are feasible to construct, considering construction methods, equipment, and labour availability.

Do the site logistics allow the substructure types chosen to be constructed safely?

Are there any neighbouring properties that could be affected?

8. Environmental Factors: Consider environmental conditions like exposure to harsh weather, chemicals, or corrosive agents, and design accordingly.

Is the structure likely to come in contact with any harsh conditions?

9. Local Regulations: Comply with building codes and regulations related to foundations, seismic design, safety, and load-bearing capacities.

10. Expansion and Contraction: Account for thermal expansion and contraction of materials in the design to prevent cracking and structural issues.

11. Resilience: Design for the long-term resilience of the substructure against potential changes in use, loads, or environmental conditions.

12. Cost Effectiveness: Strive for an efficient design that balances performance and costs while meeting safety requirements.

Definitions

Pile Cap – A concrete platform on top of a number of piles, distributing loads from columns and providing stability for foundation structures

Section – a drawing that displays a vertical or horizontal cut through the element. Shows details and dimensions.

Bearing Capacity – maximum weight/loading that a soil can support without excessive settlement or failure

Settlement – downward movement of a building foundations into the ground. Think of the structure sinking down due to its weight.

Dead Load – the permanent, unchanging weights imposed on a structure. These include the weight of the structure itself, fixtures, finishes and any non-moving equipment.

Live Load – also knows as imposed or variable loads. Temporary and dynamic forces on a structure including occupants, furniture, movable equipment and any moving vehicles.

Thermal Expansion – tendency for materials to expand when heated and contract when cooled. Alters their dimensions due to more or less molecular activity.

Posts to Follow

We plan to go into more details on Substructure and add sections on:

- Types of Substructure

- Logistics

- Temporary Works

- Build Sequence

- Health, Safety & Environment

- Quality

- Programme

- Commercial

Please let us know if you found this post useful using the chat function. We’d love to hear from you – is there anything in particular you’d like for us to focus on next?